Carbon steel knives are often regarded as high-maintenance blades that shine in one aspect while lacking in another…

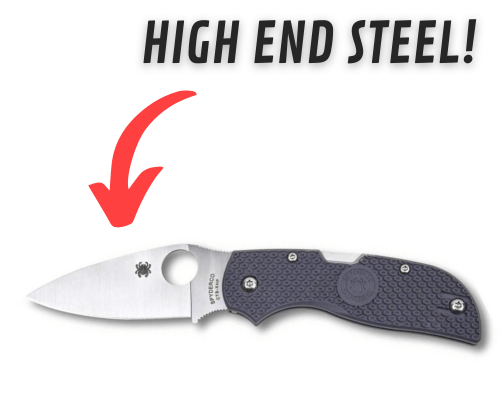

However, CTS XHP Steel is one such blade steel that checks all the boxes of the perfect steel alloy for knife making…

This steel alloy is made in the USA and is being used for manufacturing some of the highest-quality knives available today…

CTS XHP steel is unique in many aspects and stands out among other steel alloys…

That is because the composition and manufacturing process of CTS-XHP steel knives has been carefully chosen and perfected for making high-end blades…

So if you are a knife enthusiast or simply want to buy a knife made from CTS XHP steel, then you probably want to learn more about this blade steel…

A knife’s material affects its corrosion resistance, durability, edge retention, and usage experience…

This article has covered every aspect of the CTS XHP steel knives in detail. So if you want to know what to expect from a CTS XHP steel before spending your hard-earned money on it, keep reading…

Top 7 CTS XHP Steel Knives!

What Is CTS XHP Steel?

Before we move towards how this steel performs when turned into a knife, it is important to explain what this alloy is all about.

This steel is made by Carpenter Technology which is a US-based manufacturer.

Due to its durability, they manufacture this steel for knifemaking and tool manufacturing.

CTS XHP steel has been used as the go-to material for higher-end knives. Since Carpenter Technology officially makes this alloy, it is considered a rare and exclusive material.

This alloy is still a form of high-carbon steel, so it offers an authentic experience for carbon knife enthusiasts.

The manufacturing process of this steel alloy is also unique, and it gives this steel alloy its highly sought-after characteristics. CTS XHP steel knife is made using the powder metallurgy process by Carpenter Technology.

What Is The Composition Of CTS-XHP Steel?

Carpenter Technology uses a precise combination of elements in carefully measured percentages to manufacture the CTS XHP steel alloy.

The combination of these elements gives this alloy its reputation for high quality and durability.

Without further ado, here is the composition of the CTS XHP steel alloy:

- Carbon: 1.60%

- Chromium: 16%

- Molybdenum: 0.08%

- Manganese: 0.5%

- Silicone: 0.40%

- Nickel: 0.35%

- Vanadium: 0.45%

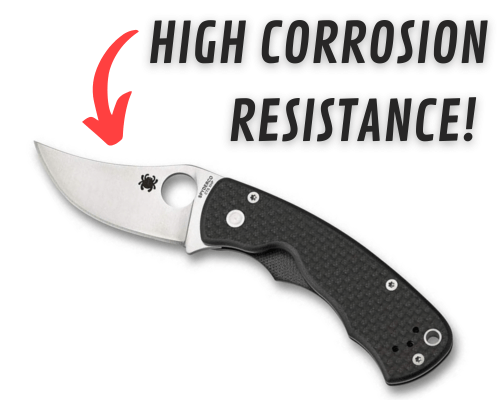

As you might have noticed, this steel alloy has 16% chromium content, which is more than most carbon steel alloys. As a result, the corrosion resistance of this alloy is second to none.

Mechanical Properties Of CTS XHP Steel

The mechanical properties of the CTS XHP alloy are impressive. Here is a list of the mechanical properties of this alloy:

- Density: 0.2750 lb/in³

- Compressive yield strength: 347.0 ksi

- Hardness: 60 to 64 HRC

- Stress relieving: 12000F

The hardness of the CTS XHP steel is much higher than most steel alloys used in knife making.

Physical Properties Of A CTS XHP Steel Knife

Now that you know this steel alloy’s chemical and mechanical properties, you may be wondering what they mean.

Every compound in this alloy and its mechanical properties create desirable physical properties that knife enthusiasts admire. With that said, here are the physical properties of the CTS XHP steel knife:

Hardness: As mentioned above, the hardness rating of the CTS XHP steel is up to 64 HRC, which is considered above average. The high hardness rating makes the CTS XHP steel knives more brittle, which may seem a drawback at first glance.

However, despite its high hardness rating, the CTS XHP steel knives demonstrate decent toughness and don’t chip easily under rough use.

Edge retention: Edge retention has always been debated about a specific type of steel alloy. CTS XHP steel is made using a powder metallurgy process, which effectively distributes carbides giving knives excellent sharpness.

Regarding retaining its sharpness, knives made from this alloy don’t lose their edge quickly. So if you are looking for a knife that can hold its sharpness, then getting one made out of this alloy is a good idea.

Wear resistance: Wear in knives refers to chipping, scratches, and other forms of damage that come from regular use. Since the vanadium content in the CTS XHP steel is not high, the wear resistance of knives made out of this alloy is also not too impressive.

This means your CTS XHP steel knife may develop superficial scratches and marks after some time.

Now that being said, the wear resistance of this steel is still better than other forms of steel available. So even though its wear resistance is not exceptional, it still gets the job done better than other alloys.

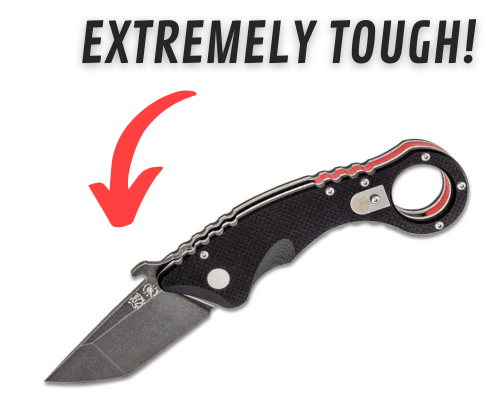

Toughness: Despite its high hardness, CTS XHP steel knives shine when it comes to toughness.

You can put this knife to outdoor use and chop small branches and some wood without worrying about your knife losing its edge.

So if you are looking for a knife to add to your survival or camping kit, this alloy can be used for rugged applications.

Corrosion resistance: Knives made from CTS XHP contain a high amount of carbon which makes them high-carbon knives. If you know anything about knives, you probably know that high-carbon knives are notorious for corrosion.

Despite its high carbon content, this alloy also contains high amounts of chromium, which offer excellent corrosion resistance.

So you won’t have to worry about your CTS XHP steel knife rusting anytime soon. You can use this alloy in high humidity and corrosive environments without ruining the color and pattern of your knife.

High corrosion resistance makes this alloy ideal for making pocket knives that are used for outdoor activities.

However, you can find knives made out of this alloy in kitchens as well since it can withstand exposure to water, salt and similar corrosive elements.

Once you buy a CTS XHP steel knife, you will not have to worry about rust as long as you are performing regular maintenance on your knife.

Ease of sharpening: Unlike stainless steel, carbon knives can be sharpened, and some are easier to sharpen than others.

When talking about CTS XHP steel alloy, it is moderately easy to shave off thin layers of the knife’s edge using a regular sharpening tool.

This alloy doesn’t chip during sharpening either, so even if you are not an expert at sharpening knives, you can still shape a CTS XHP blade easily.

Pros And Cons Of CTS XHP Steel Knives

Now that we have gone through various aspects of CTS XHP knives in detail, it is time to sum up, the pros and cons of this steel alloy mentioned throughout the article.

Here are some pros and cons of CTS XHP steel knives that you should know about:

Pros:

- It can withstand heavy usage without damaging or dulling the blade.

- You can use a CTS XHP steel knife in humid and corrosive conditions, which is not possible with a majority of carbon steel knives.

- It offers a premium feel to the user and has an aesthetic appeal to it.

- When used in survival situations, the knife can go for prolonged periods of time without losing its sharpness. This benefit of CTS XHP knives comes especially handy in situations where frequent sharpening is just not an option.

Cons:

- This steel is manufactured by a few manufacturers, which makes knives made from this alloy difficult to find.

- The scarcity of this alloy makes knives made out of CTS XHP expensive.

- The high hardness of this knife may be too much for some users.

What Are Some Usage Applications Of CTS XHP Steel Knives?

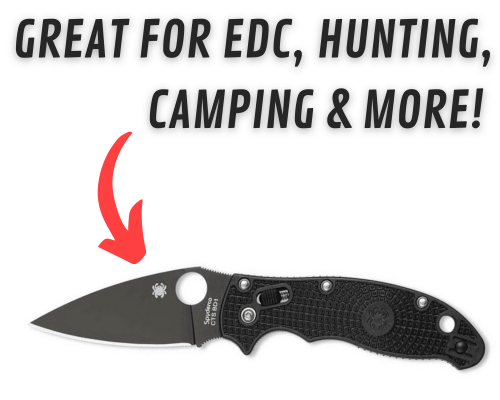

CTS XHP steel is mostly used for making pocket knives because they have a smaller blade which can benefit from the high hardness of this steel.

A longer blade made out of this steel may not perform well because of a lack of flexibility.

So if you are looking to buy a pocket knife for hunting, fishing, survival, camping and other outdoor usage applications, then a CTS XHP knife might do the trick.

However, there are situations where this steel alloy may be used for utility applications and even in kitchens.

While the use of this steel alloy for making knives other than pocket knives is not common, it is definitely possible. And you may even come across plenty of kitchen knives made from this alloy.

Top 7 CTS XHP Steel Knives!

CTS XHP Steel – Final Thoughts…

CTS XHP steel is a rare yet highly sought-after material for knives, and enthusiasts are willing to pay a good amount of money to get their hands on a knife made out of this alloy.

While CTS XHP knives may have high hardness, they more than makeup for it in almost every other aspect.

So if you are looking for a knife that can go for long periods without needing sharpening but can be sharpened quickly and easily, then go for this alloy.

To sum it all up, you will not regret purchasing a knife made out of CTS XHP steel as long as you know its limitations and use it for the correct purposes.